Bending

Precision, reliability and efficiency

Bending

Precision, reliability

and efficiency

Startseite » Mayer Laser & Sheet Metal Technology » Competencies » Bending

Precision, reliability and efficiency

In addition to laser cutting, bending is one of our core competencies. Our current machinery includes four CNC press brakes with a maximum bending length of 4,420 mm and a press force of 3,200 kN. Whether single or series bending, bending difficult shapes, tight radii or small leg lengths, we offer fast cycle times and consistently high quality. The trained and experienced technical staff works in 3-shift operation and enables short delivery times as well as uncompromisingly high angular accuracy.

Our press brakes

Manufacturer

Power

Range

1 x

Press brake

Trumpf TruBend 5320

3,200 kN

max. edge length: 4,420 mm

1 x

Press brake

Trumpf TruBend 5230

2,300 kN

max. edge length: 3,230 mm

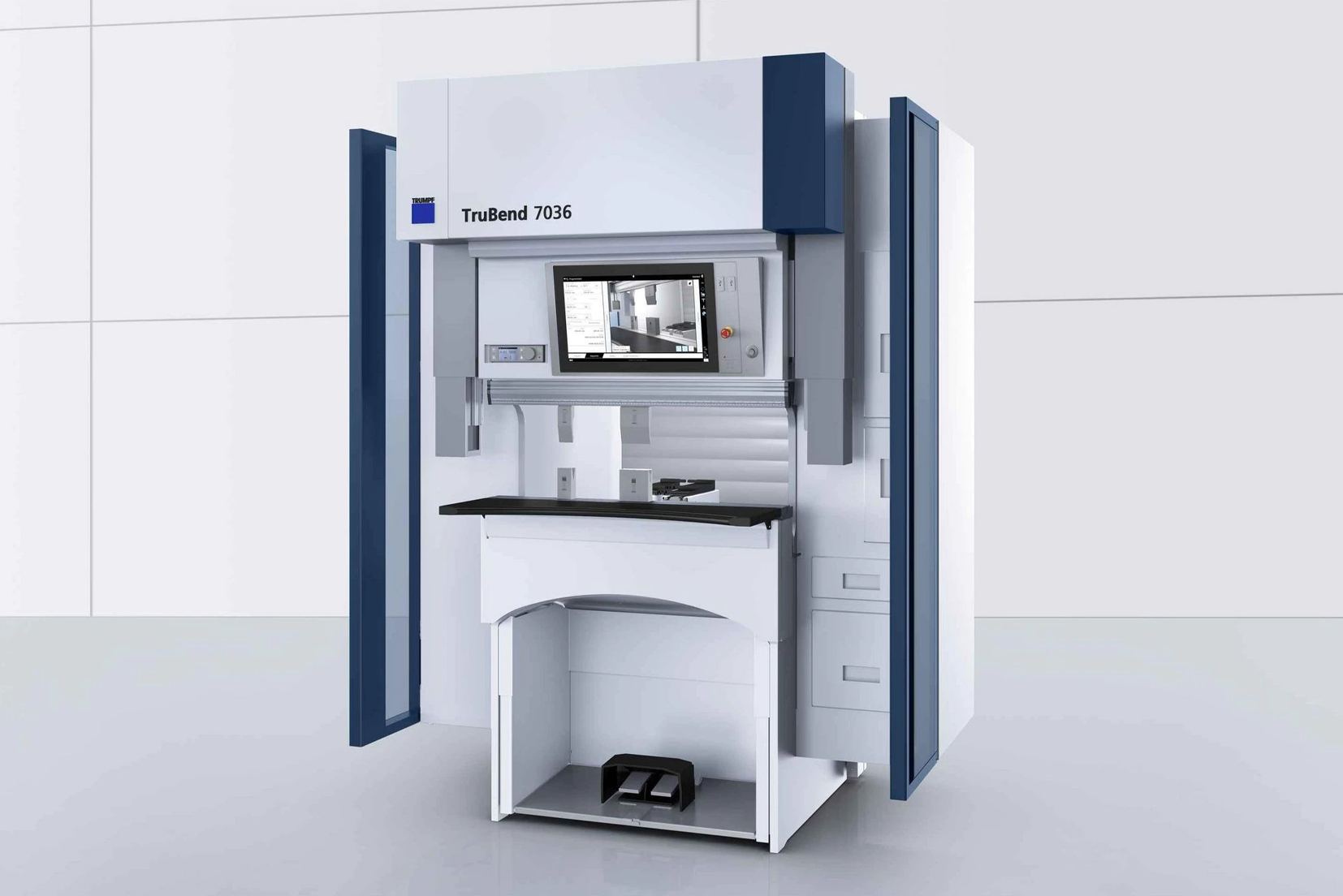

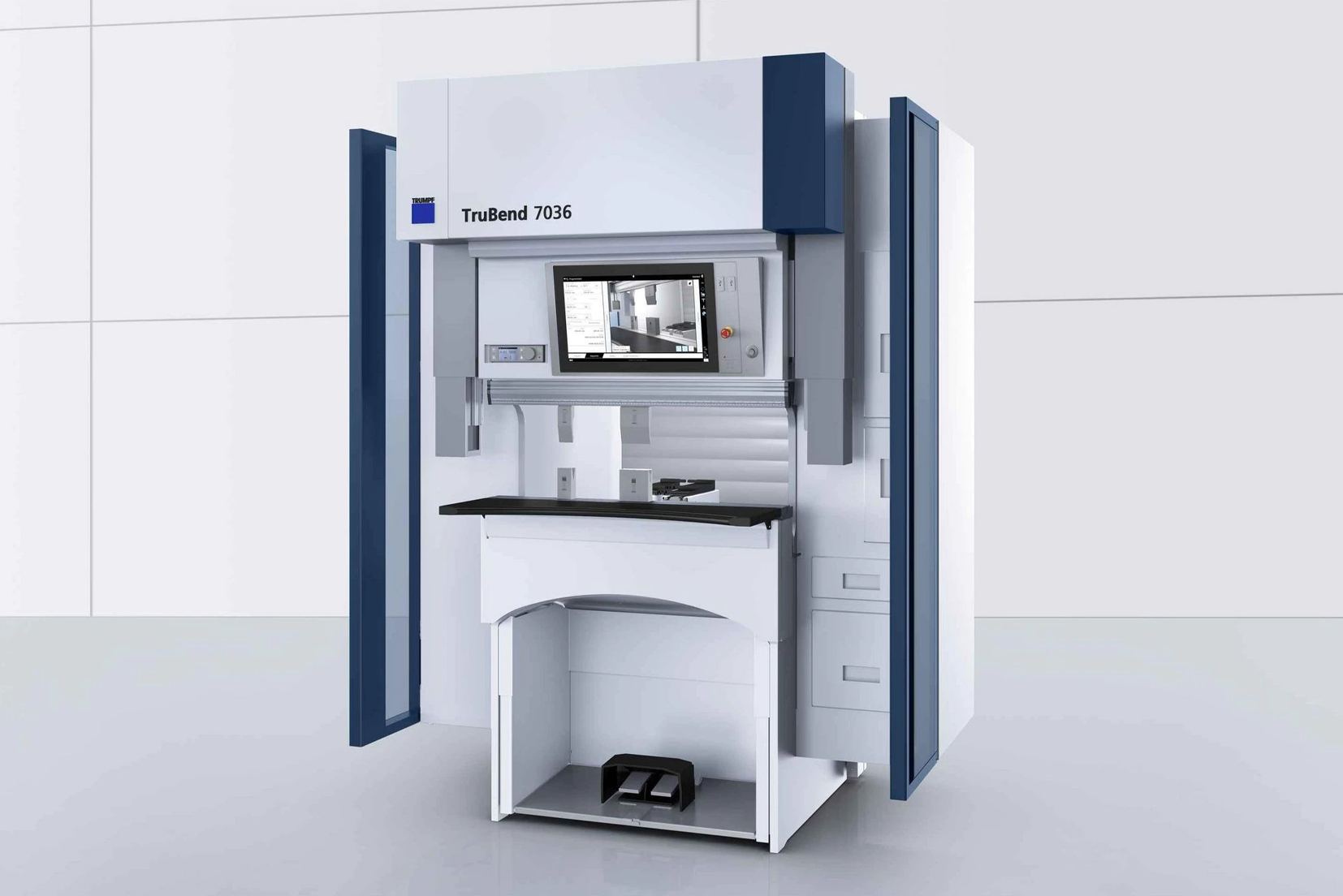

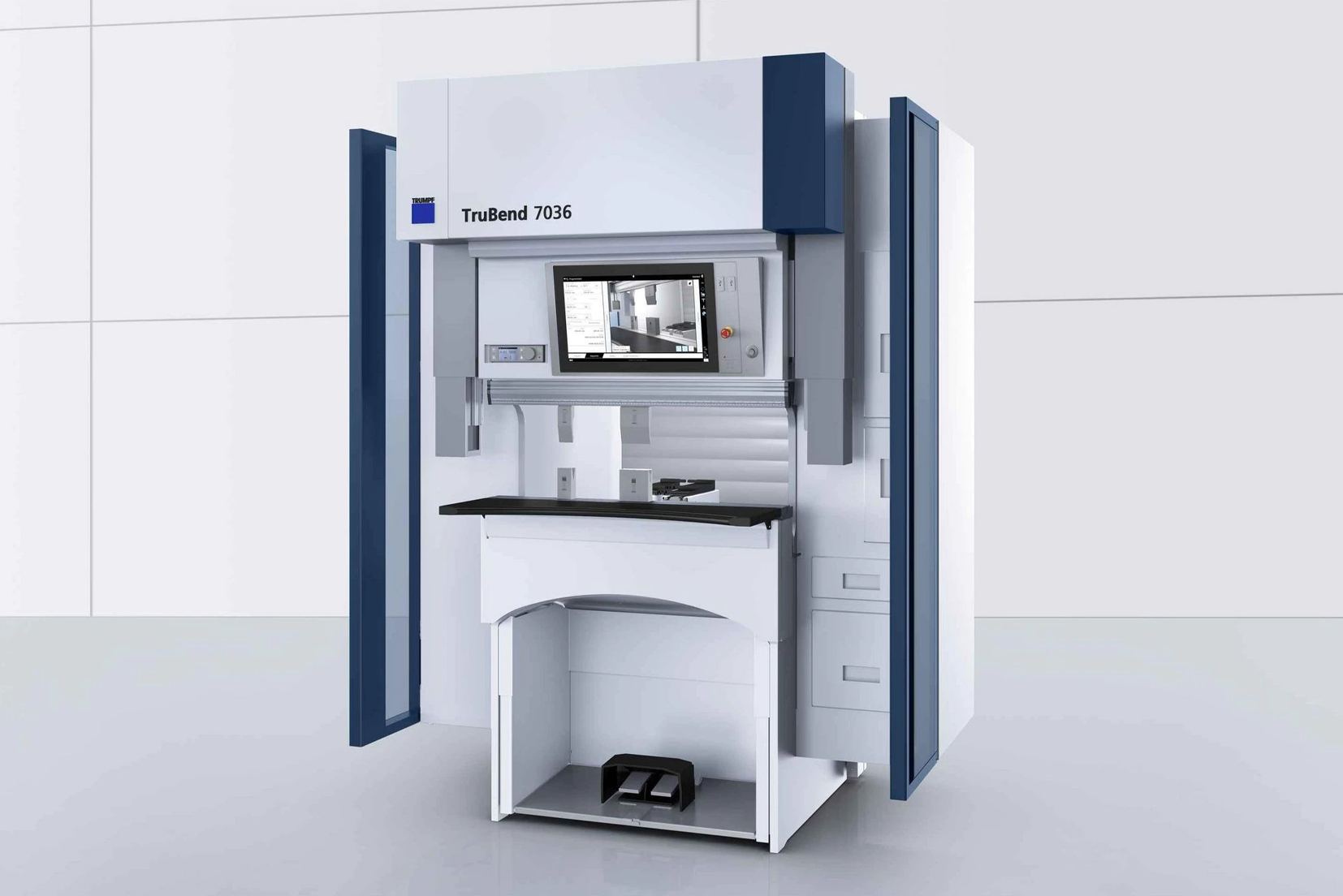

1 x

Press brake

Trumpf TruBend 7036

360 kN

max. edge length: 1,020 mm

Manufacturer

Power

Range

1 x

Press brake

Trumpf TruBend 5320

3,200 kN

max. edge length: 4,420 mm

1 x

Press brake

Trumpf TruBend 5230

2,300 kN

max. edge length: 3,230 mm

1 x

Press brake

Trumpf TruBend 7036

360 kN

max. edge length: 1,020 mm

1 x Press brake

Trumpf TruBend 5230

Power:

3,200 kN

max. edge length: 4,420 mm

1 x Press brake

Trumpf TruBend 5230

Power:

2,300 kN

max. edge length: 3,230 mm

1 x Press brake

Trumpf TruBend 7036

Power:

360 kN

max. edge length:

1,020 mm

Method for bending

Bending is one of the non-cutting sheet metal forming processes and is often also referred to as edging or bending. In this process, a sheet metal plate is formed with the help of a press brake and by applying mechanical force. A press brake has an upper tool (punch) that is pressed into a lower tool (die). By lowering the punch, the intervening sheet metal is bent into the desired shape. To make the bending process as efficient as possible, the sheet to be bent is placed against a stop. Bending processes can be simulated with the aid of the CNC control, allowing the optimum plunge depths to be planned even without trial bends. In addition to angles, radii can also be bent on a modern press brake.

Your advantages at a aglance

Highest

angle accuracy

3 shift

operation

Cost-efficient

CNC programming

Short

delivery times

Highest

quality

Highest

angle accuracy

3 shift

operation

Cost-efficient

CNC programming

Short

delivery times

Highest

quality

Our further competencies

We are here for you!

Do you have questions about our services or need assistance? We are happy to support you personally.

We are looking forward to your message.

- IMPRINT

- DATA PROTECTION

- GTC