Machinery

Startseite » Mayer Laser- & Sheet Metal Technology_A » Machinery

Discover our machinery

Our modern machinery and our unique vertical range of manufacture on an area of more than 20,000 qm² at our Hungarian location, enables us to react quickly and to provide short delivery times. Benefit from our cost-efficient core competencies, such as laser cutting, bending, deburring, powder coating and thin sheet welding in various processes.

Our laser cutting machines

Our laser cutting machines

Manufacturer

Power

Range

Manufacturer

Power

Range

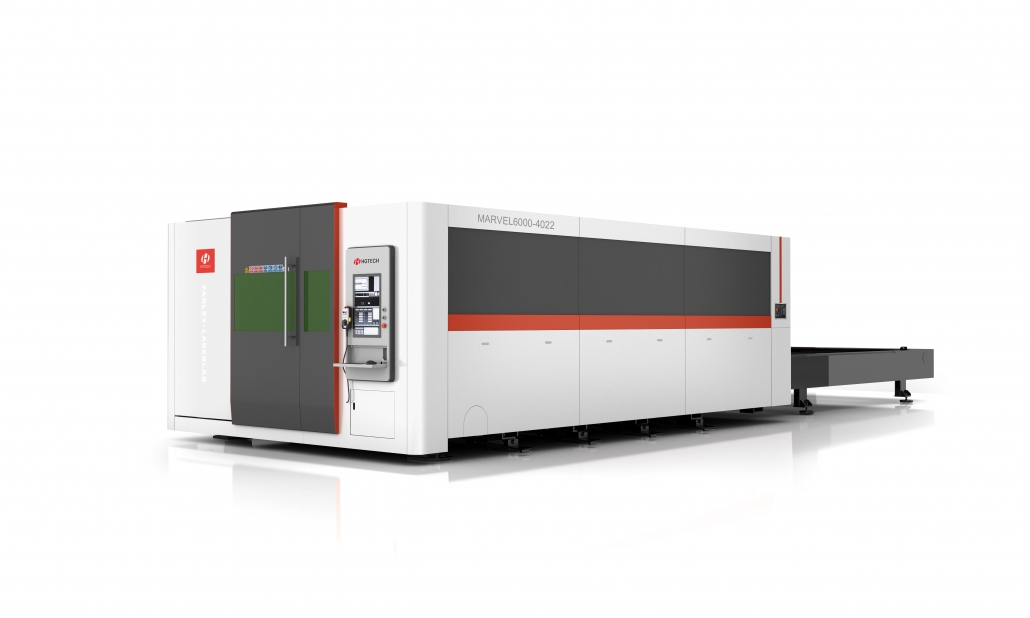

HGTECH Marvel 6000 Fiber

1 x

Laser cutting machine

HGTECH Marvel 6000 Fiber

6 kW

X: 4.000 mm

Y: 2.200 mm

HGTECH Marvel 6000 Fiber

1 x

Laser cutting machine

HGTECH Marvel 6000 Fiber

6 kW

X: 4.000 mm

Y: 2.200 mm

1 x Laser cutting machine

HGTECH Marvel 6000 Fiber

HGTECH Marvel 6000 Fiber

Power:

6 kW

X: 4.000 mm

Y: 2.200 mm

Trumpf TruLaser 3030 Fiber

1 x

Laser cutting machine

Trumpf TruLaser 3030 Fiber

6 kW

X: 3.000 mm

Y: 1.500 mm

Trumpf TruLaser 3030 Fiber

1 x

Laser cutting machine

Trumpf TruLaser 3030 Fiber

6 kW

X: 3.000 mm

Y: 1.500 mm

1 x Laser cutting machine

Trumpf TruLaser 3030 Fiber

Trumpf TruLaser 3030 Fiber

Power:

6 kW

X: 3.000 mm

Y: 1.500 mm

Trumpf TruLaser 3030 CO2

1 x

Laser cutting machine

Trumpf TruLaser 3030 CO2

5 kW

X: 3.000 mm

Y: 1.500 mm

Trumpf TruLaser 3030 CO2

1 x

Laser cutting machine

Trumpf TruLaser 3030 CO2

5 kW

X: 3.000 mm

Y: 1.500 mm

1 x Laser cutting machine

Trumpf TruLaser 3030 CO2

Trumpf TruLaser 3030 CO2

Power:

5 kW

X: 3.000 mm

Y: 1.500 mm

Our press brakes

Our press brakes

Manufacturer

Power

Range

Manufacturer

Power

Range

Trumpf TruBend 5320

1 x

Press brake

Trumpf TruBend 5320

3,200 kN

max. edge length:

4,420 mm

Trumpf TruBend 5230

1 x

Press brake

Trumpf TruBend 5230

2,300 kN

max. edge length:

3,230 mm

Trumpf TruBend 5320

1 x

Press brake

Trumpf TruBend 5320

3,200 kN

max. edge length:

4,420 mm

Trumpf TruBend 5230

1 x

Press brake

Trumpf TruBend 5230

2,300 kN

max. edge length:

3,230 mm

1 x Press brake

Trumpf TruBend 5320

Trumpf TruBend 5320

Power:

2,300 kN

max. edge length:

4,420 mm

1 x Press brake

Trumpf TruBend 5230

Trumpf TruBend 5230

Power:

2.300 kN

max. edge length:

3.230 mm

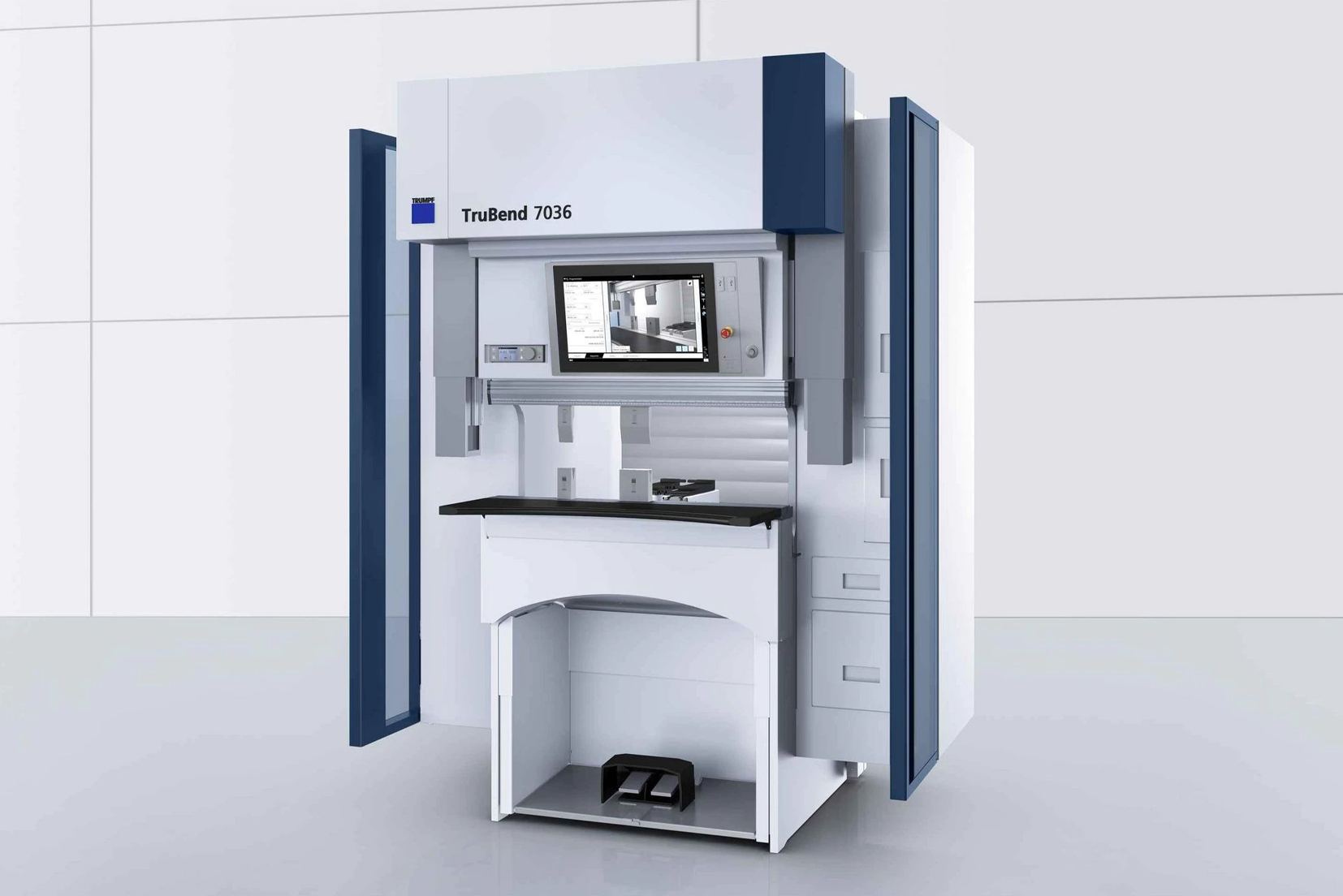

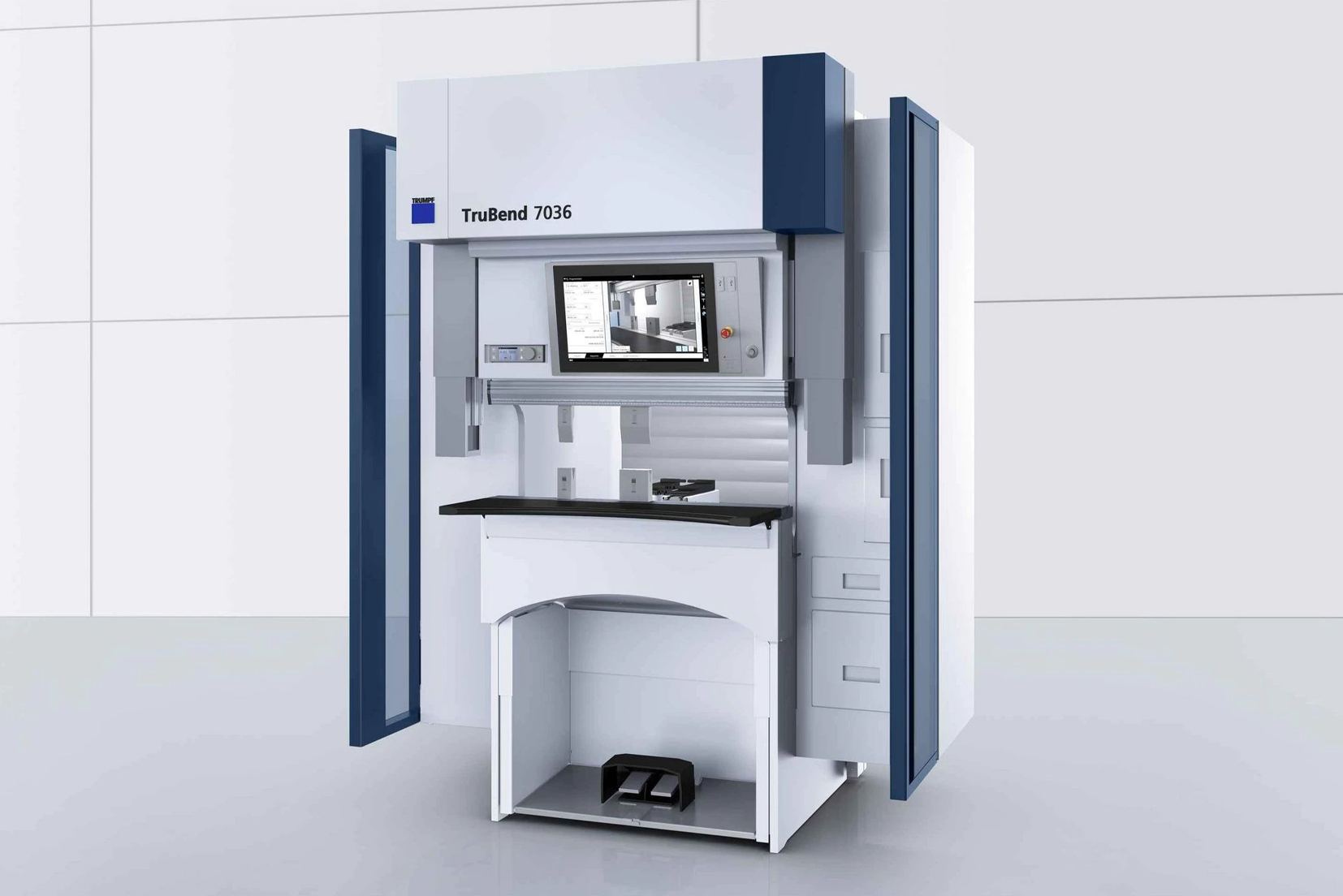

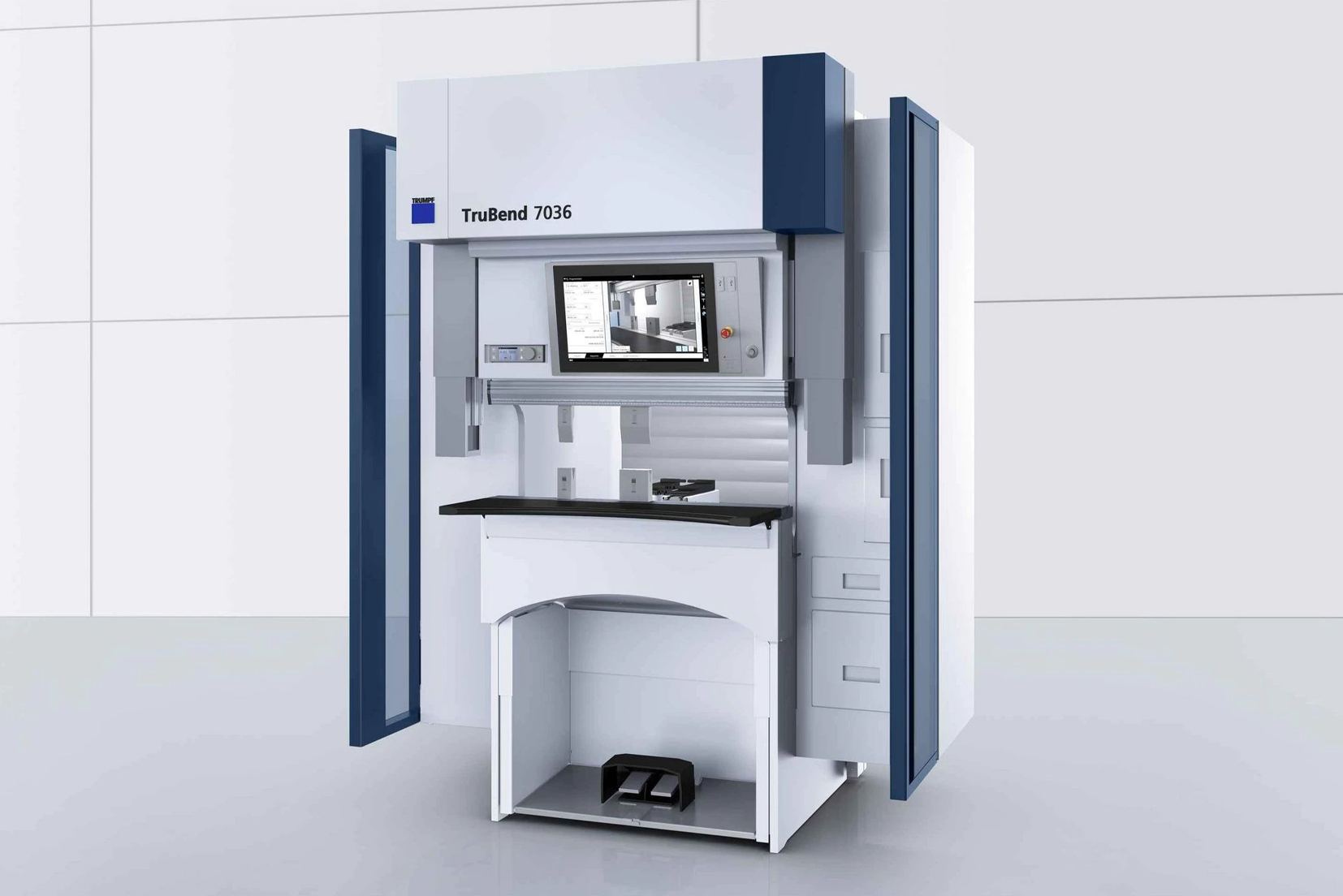

Trumpf TruBend 7036

1 x

Press brake

Trumpf TruBend 7036

360 kN

max. edge length:

1,020 mm

Trumpf TruBend 7036

1 x

Press brake

Trumpf TruBend 7036

360 kN

max. edge length:

1,020 mm

1 x Press brake

Trumpf TruBend 7036

Trumpf TruBend 7036

Power:

360 kN

max. edge length:

1,020 mm

our rotary brush machine

Our rotary brush machine

Manufacturer

Machining possibilities

Manufacturer

Machining possibilities

Timesavers 42 RB series

1 x

Rotary brush machine

Timesavers 42 RB series

– Deburring

– Finish grinding

– Edge rounding

– Oxide layer removal

Timesavers 42 RB series

1 x

Rotary brush machine

Timesavers 42 RB series

– Deburring

– Finish grinding

– Edge rounding

– Oxide layer removal

1 x Rotary brush machine

Timesavers 42 RB series

Timesavers 42 RB series

– Deburring

– Finish grinding

– Edge rounding

– Oxide layer removal

Learn more about our competencies

We are here for you!

Do you have questions about our services or need assistance? We are happy to support you personally.

We are looking forward to your message.

- IMPRINT

- DATA PROTECTION

- GTC