Contract metrology

New measuring hall & Large portal measuring machine

at the Heidenheim location

Startseite » Mayer Steel- & Apparatus Engineering » Competencies » Contract Metrology

Master in the royal class

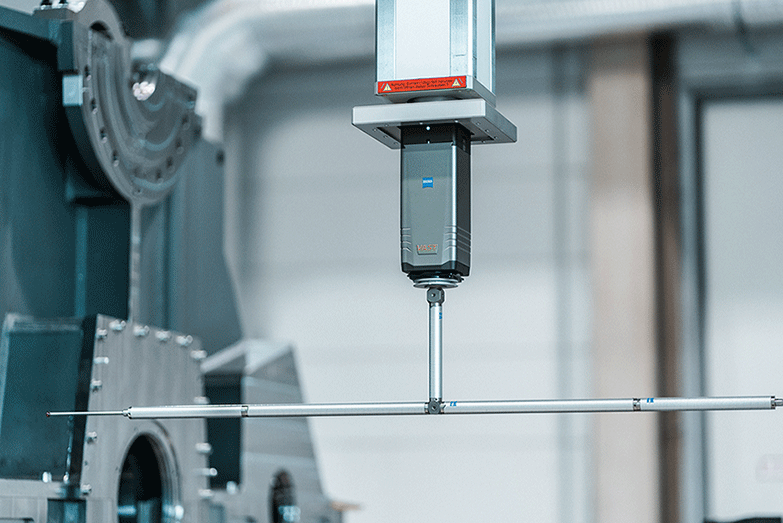

Another great leap towards the future. On August 15, 2019 the new large portal measuring machine of the company Bometric Industrielle Messtechnik GmbH from Augsburg was put into operation within our factory halls at the location in Heidenheim. The hall offers the largest measuring volume of all measuring machines from Carl Zeiss with unsurpassed accuracy. This makes it ideal for inspecting large, complex parts. In order to ensure high accuracy at every accessible measuring point, the MMZ G series features computer-aided error correction of the movement axes (Computer Aided Accuracy, CAA). The quill and measuring head are collision protected as standard.

The air-conditioned measuring hall forms an innovative cooperation between a paver and a surveyor. Coupled with the latest measuring technology, an excellent basis is created for you and us for even more transparency in terms of quality, flexibility and short processing times.

Your advantages at a glance

Large measuring volume

Guaranteed by various procedures

Highest precision

With a measuring accuracy of 10 mµ (0,01 MM)

Customized consulting

We are happy to support you in your project and advise you on the possibilities of measuring your component.

Large portal measuring machine

MEASURING VOLUME

Y: 7.000 mm

X: 4.000 mm

Z: 3.000 mm

PRECISION

Length measurement deviation

[μm] starting at 2,2 + L/400 < 12

Large measuring volume

This Zeiss MMZ G large portal measuring machine is characterized by its large traverse paths of 7.000 mm x 4.000 mm x 3.000 mm (L/W/H). Despite its large measuring volume, it is suitable for testing complex and very precise workpieces in the µm (micrometer) range. In order to achieve the standard-compliant measuring situation of +/-1°C per day within the measuring hall, a specially adapted air conditioning system is installed. An attached intermediate hall serves for pre-tempering of the components to be measured.

Exact solutions

Drives free of lateral forces avoid excessive wear. The forward-looking Zeiss VAST technology delivers highly precise results with its sensors, since they can be calibrated and scanned quickly. In addition, the Thermofit XL key extension allows very deep bores to be measured accurately. And the Zeiss MMZ G remains intelligent. An accessible measuring range and a view of the measuring volume from all sides enable effective analysis directly on the workpiece. Due to its simplified, intelligent operation, the Zeiss MMZ G fits ideally into our progressive future strategy. Optical collision detection and protection are further factors for uncompromising safety while maintaining the highest standards of precision and quality.

We are here for you!

Do you have questions about our services or need assistance? We are happy to support you personally.

- +49 7321 9594 0

- +49 7321 9594 299

- anfrage@mayer.de