The 1950s were a time of change and reconstruction in Germany. West Germany in particular experienced steady growth in the 1950s, supported by the European Recovery Program (also known as the Marshall Plan). Low wages combined with a high degree of innovation & automation brought economic growth to West Germany, which has gone down in history as the economic miracle. At the same time, the gap between East and West Germany grew steadily and became wider than ever with the construction of the Berlin Wall in the 1960s. The increasing prosperity in West Germany led to increased demand in all sectors of the economy. This was also the case in commercial horticulture and especially in the demand for pot plants.

From Vision to reality

Georg Mayer, the father of the current owner of the Mayer Group, Klaus Mayer recognized that the traditional, manual pot-filling and planting method, both qualitatively and quantitatively, could not keep up with the increased demand. From this point on together with Alfred and Herbert Haufe, at that time two of the leading German heather and azalea growers, he developed the vision of making the production process of horticultural companies as simple and efficient as possible.

Due to his background as a mechanical engineer, he developed several prototypes to automate the pot-filling process. In 1967, the time had finally come, and he achieved his breakthrough. Georg Mayer developed a machine that would change the commercial horticulture industry forever. Equipped with an automatic drill motor, the “Model 68” went down in history as the first automatic potting machine in the world and has inseparably linked the name Mayer with the invention of the potting machine. The first potting machine had a small soil container which was mounted on a round system from which the pots could be filled with soil. The drill motor attached to the slewing ring was the first automation in the potting process and was a great time saver, enabling horticultural businesses to increase their production output while maintaining a consistently high pot quality.

Becoming the Leader in Innovation

With the success of the “Model 68”, the second machine, the “Model 69”, followed in 1969 and only two years later, the third machine the “Model 71” was introduced to the market. Both machines had an automated substrate transport system that automatically transported the soil to the slewing ring. Over the following years, the machines were continuously developed further and received a conveyor belt with elevator chains, which not only transported the soil from the soil bunker to the machine but also filled the pots on the slewing ring automatically at the same time.

Mayer as a Seal of Quality

From previous experiences in the production of agricultural machinery and large steel & metal constructions, it became clear to Georg Mayer that the potting machines he developed, not only had to function perfectly, they also had to be built to last and to withstand the extreme conditions of daily use.

Over the years, Mayer has become renowned not only for the invention of the first potting machine but also for the high quality and long service life of the machines. Even today, machines which were delivered 40 years ago are still in use, supporting gardeners in their daily work, just like on the first day.

This demand for quality and the development of automation solutions, close to the needs of our customers, have been the focus of our activities for over 50 years.

Mayer Planting Systems Today

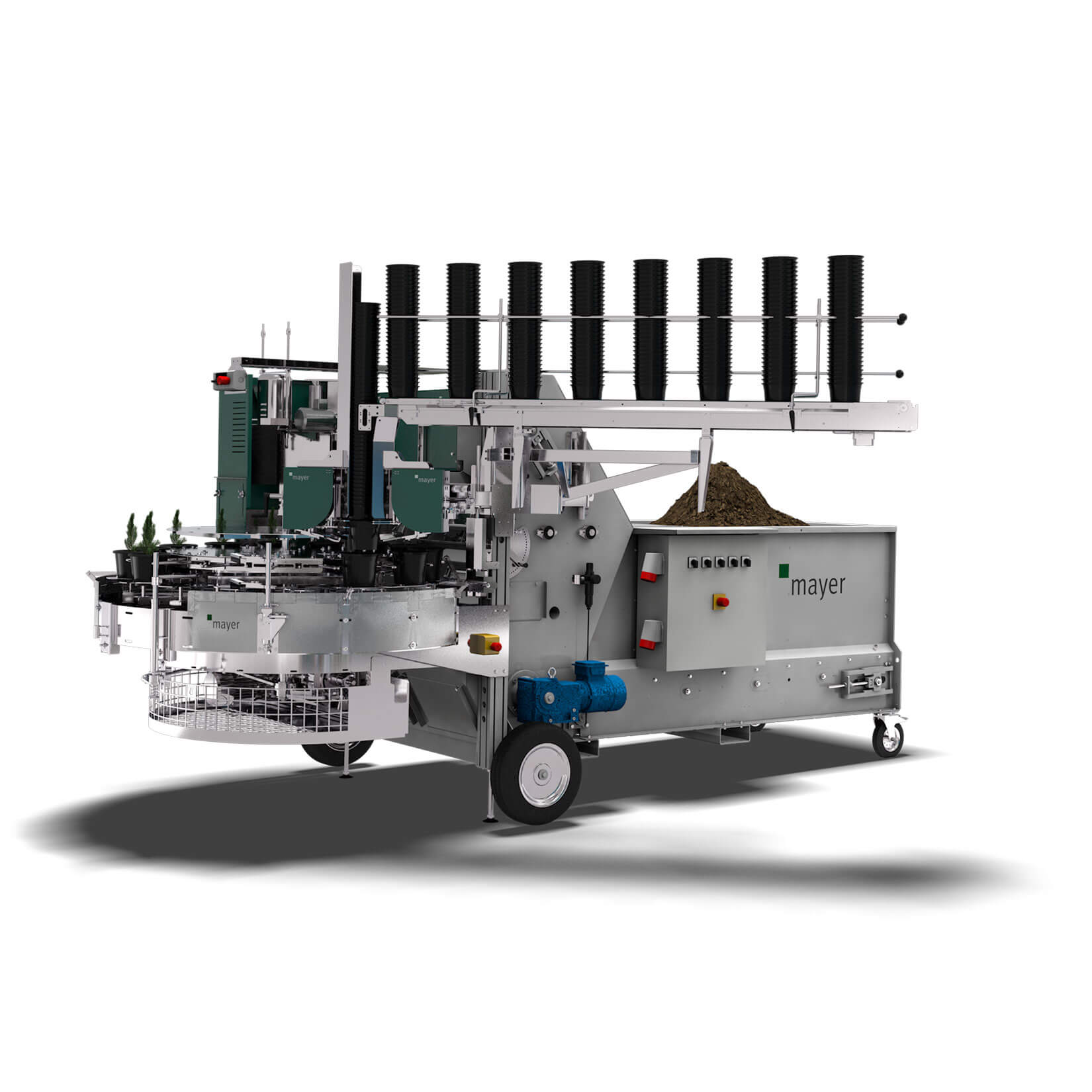

Over the years, not only the portfolio, which now includes machines for soil preparation, filling and handling, has been continuously developed. The company has also reinvented itself time and time again and has been continuously expanded.

Mayer TM 2400E

Mayer TM 2400E

Mayer Modell 68

Mayer Modell 68

With the production at the Heidenheim site, however, the production limit was quickly reached due to the high demand. To meet the growing demand for automation solutions for commercial horticulture, the first foreign subsidiary was founded in 1994 in Kisfalud, Hungary. This was followed in the same year by the establishment of the second foreign subsidiary of Mayer HW & SW Kft, which from then on was responsible for the development and manufacturing of switch cabinets, control technology and handling equipment such as conveyor belts.

Our product catalog is now also available for download. Discover our product variety and the possibilities of process automation for substrate preparation and the filling and handling of pots and trays.

Discover our product portfolio, such as the Mayer TM 2400E potting machine, our excellent Mayer Potjet 2 pot magazine, the Mayer WT 8000 irrigation tunnel or the new, improved Mayer TM 1610F.